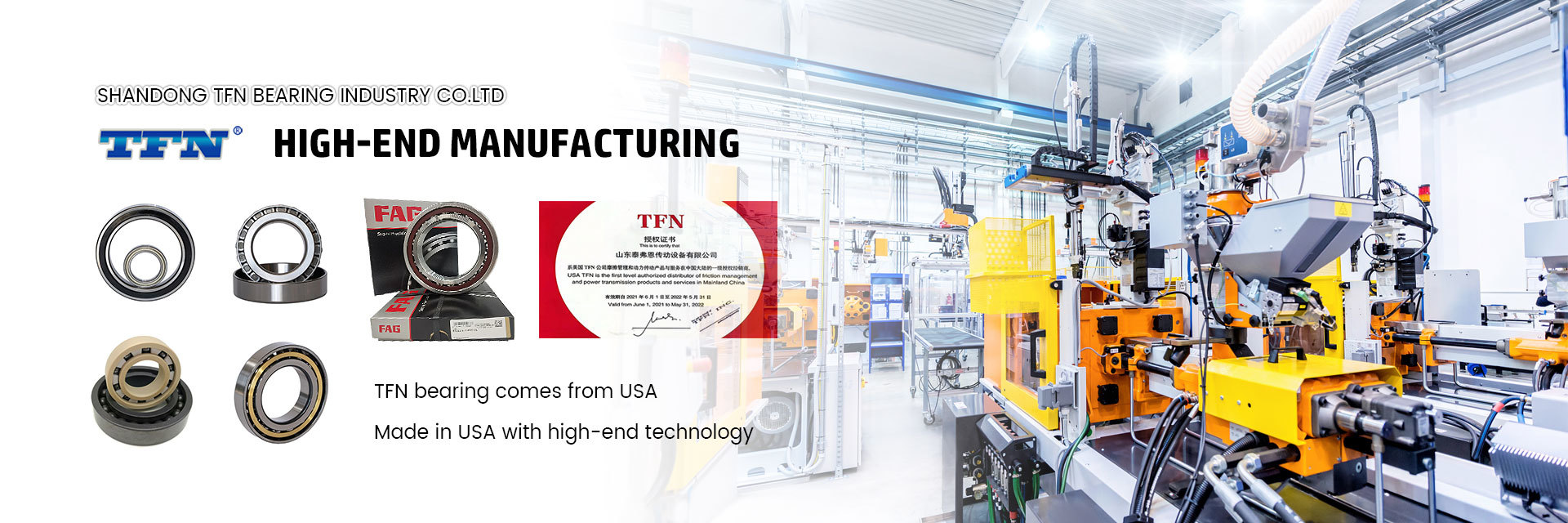

HIGH END BEARING : TFN

HIGH PRECISION POINT BEARING

GENERAL BEARING

Shandong TFN Bearing Industry Co.Ltd

ABOUT US

BEARING

We are a professional bearing manufacturer and exporter. Due to business development and growth, in order to better develop and connect with foreign markets, a branch company Tianjin Greener Machinery Equipment Co., Ltd. was established in 2022.

TECHNOLOGY

We have a wealth of technology. All production processes are done in our factory. As an ISO9001:2000 certified manufacturer, we will solve various problems in the application and use of our bearings.

BRAND

Our company is the authorized dealer of FAG, INA, TIMKEN and other world brand bearings. Our company has the right to export bearings independently, and has launched its own brand RTB.

EXPORTED

Our bearings have been exported to more than twenty countries around the world and are warmly welcomed. We look forward to your order.

Bearing type

Area covered

Annual sales

Total number of employees

NEWS

FAQ

1.Is the company a production factory or a trading company?

2.How many the MOQ of your company?

3.Does the company accept OEM or customized bearings?

4.What are the company's delivery terms?